In the field of packaging hot stamping is the process of using heat and pressure to apply metallic foil or holographic foil on materials like paper boards, papers, laminated boards, corrugated boxes etc. The stamping process is durable, cost effective and flexible. Due to its numerous features hot foil stamping is now being used in multiple industries.

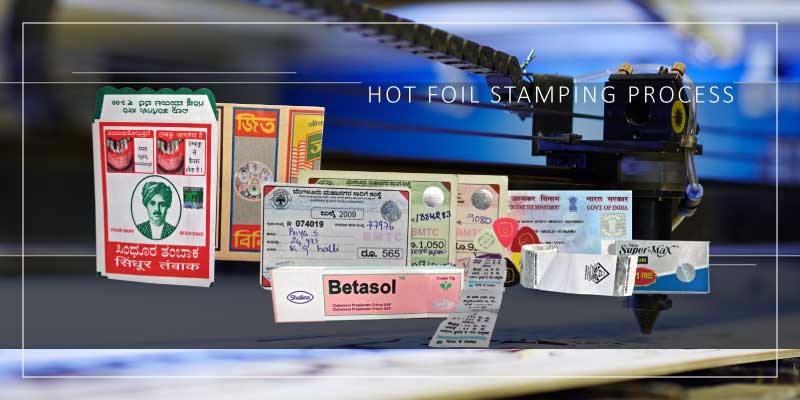

Lately, the process is being used on a wide range of products to give a decorative look and provide anti-counterfeiting features. Some of the industries where hot foil stamping is used include luxury goods packaging, tobacco, pharma, food and on product labels of high-end products. Foil stamping is also used in gift wrapping, wedding invitations, and much more.

Hot stamping holographic foils are made up of multiple layers. The layers include a polyester carrier, a release liner, a layer of lacquer, images etc. In the hot foil stamping process heated die forces the foil against a substrate which is held firm by a counter cylinder. The double combination of pressure and heat activates the adhesive lining and the foil attaches to the substrate

Hot foil stamping offers many benefits which can summarized under the following points:

Hot stamping is durable: The packaging of your product has to face harsh environment of the supply chain. Hot stamping is highly durable in nature and can withstand severe conditions.

Hot foil stamping provides aesthetic looks: One of the primary features of hot foil stamping is that they have a lustrous appeal which attracts the consumers.

Hot foil stamping can be customised: You can ask for a customised look and features in hot stamping foils.

Holostik is a leader in providing customised hot stamping foils as per your requirements. Our holographic hot stamping foils are made of high-quality materials and can be used effectively for smart packaging needs. To know more about our hot stamping foils, you can call us on +91–785-785-7000 or drop us a mail at connect@holostik.com.