Poor inventory management system leads to a plethora of inefficiencies such as disrupted supply chain visibility, manual processes & unwanted delays which drastically impact profitability

Our Clients

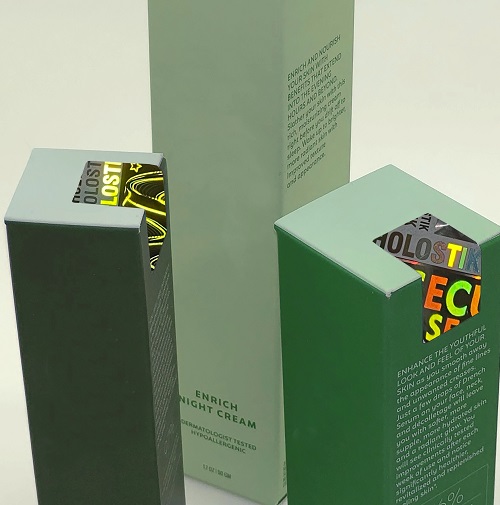

Ensuring Supreme Brand Protection

Why should you choose Holostik Inventory Management System?

Holostik is a leading player in providing customised inventory management solutions. We provide inventory management solutions through our smart labels and phygital security solutions. Being a CMMI Level 3 certified company, we abide by defined processes and efficient management system for enhanced productivity and profits.

Tailored to Your Industry

Trusted by 10,000+ Brands

Related Products

FAQs on Inventory Management System

1. What is an inventory management system?

An inventory management system is a digital solution that helps organizations track, manage, and control raw materials, work-in-progress, and finished goods across the supply chain. It provides real-time visibility into stock levels, movement, and usage to reduce wastage, delays, and operational inefficiencies.

2. Why is an efficient inventory management system important?

An efficient inventory management system ensures accurate stock visibility, minimizes manual errors, prevents overstocking or stockouts, and improves supply chain coordination. This leads to better production planning, optimized working capital, reduced losses, and improved overall profitability.

3. How does an inventory management system improve supply chain visibility?

Inventory management systems capture real-time data at every stage of the supply chain—from raw material intake to finished goods dispatch. This provides complete visibility across locations, warehouses, and production units, enabling faster decision-making and uninterrupted inventory flow.

4. Can inventory management reduce raw material wastage?

Yes. By providing accurate stock data and usage insights, inventory management systems help optimize raw material utilization, prevent excess procurement, reduce expiry or damage-related losses, and ensure materials are consumed as per production requirements.

5. How does inventory management help handle demand fluctuations?

An advanced inventory management system synchronizes supply with demand by analyzing real-time stock levels and consumption patterns. This allows businesses to respond quickly to demand volatility, adjust production schedules, and maintain optimal inventory levels without disruptions.

6. Can the inventory management system integrate with ERP software?

Yes. Inventory management systems can be seamlessly integrated with existing ERP, CRM, and BI platforms. This ensures unified data flow, eliminates duplication, and allows businesses to leverage their current IT infrastructure while improving operational efficiency.

7. How does inventory management reduce manual work and errors?

Automated inventory management replaces manual record-keeping and paperwork with digital tracking using smart labels and phygital technologies. This significantly reduces human errors, saves time, improves accuracy, and enhances productivity across the supply chain.

8. Which industries benefit most from inventory management systems?

Industries such as FMCG, pharmaceuticals, agrochemicals, automobiles, liquor, tobacco, electronics, BFSI, e-commerce, education, and fashion benefit greatly from inventory management systems due to complex supply chains and the need for accuracy, compliance, and efficiency.

9. Is the inventory management system scalable for growing businesses?

Yes. Modern inventory management systems are highly scalable and can grow alongside business expansion. They support increasing SKUs, multiple locations, higher transaction volumes, and evolving supply chain complexity without compromising accuracy or performance.

10. What business benefits can companies expect from an inventory management system?

Companies experience improved inventory accuracy, better cash flow, reduced operational costs, faster production cycles, improved customer satisfaction, and stronger brand reputation—resulting in long-term profitability and repeat business.